Cornell Commercial Rolling Doors and Security Grilles Blog

When it comes to Overhead Rolling Doors and Grilles, we are the experts in innovative door solutions!

Subscribe

Get updates on new blog posts to your inbox!

Understanding Insulated Rolling Doors: A Comprehensive Guide

Learn about the role and importance of insulated rolling doors in commercial building design in this comprehensive guide.

What is an insulated rolling door?

An insulated door is engineered and constructed with a core material between the slats that provides thermal resistance. The thermal performance of the door assembly is typically measured by U-factor. Insulated doors use non-metal materials such as plastic backers and rubber gaskets to create thermal breaks. This design minimizes heat transfer from one side of the door to the other, “breaking” the path of heat transfer.Function and purpose of insulated rolling doors.

An insulated door serves two purposes: to insulate and seal. Both qualities are important for an energy-efficient rolling door. While the former is important, seals can make or break a door’s overall thermal performance. These doors are typically used in buildings that need interior climate control: warehouses, cold storage facilities, food processing plants, and pharmaceutical manufacturing facilities, just to name a few.Energy Efficiency

The most important function of an insulated rolling door is to regulate indoor temperatures. Part of a full energy efficiency strategy, an insulated door can start a domino effect. First, consistent indoor temperatures lead to reduced energy consumption. Then, heating and cooling systems don’t have to work so hard. Next, reduced energy consumption leads to lower utility bills. Finally, overall energy savings results in a reduction in long-term building maintenance costs.Climate Control

Energy efficiency upgrades contribute to healthy and cozy indoor environments. Not only for employees and customers, but for equipment and goods. Insulated rolling doors are a solution to sealing the building envelope. Specialized seals and gaskets block air leaks and infiltration points, sealing gaps. This, plus high-quality insulation in the door’s core, helps balance a building’s humidity and temperature levels, preventing condensation, corrosion, mold and mildew.Sound Attenuation

Insulated doors carry an unexpected perk – sound attenuation! Or, simply, a reduction of sound or volume. Sound attention is thanks to excellent insulation materials in the door, which will either be foamed-in-place melamine, polyurethane, polystyrene foam, or mineral wool. This and a solid perimeter seal contribute to favorable sound attenuation. Its Sound Transmission Class (STC) rating measures how well a door muffles sounds. The higher the rating, the more soundproof the door.Building Codes and Standards

Like most products, insulated coiling doors are designed to meet, and even exceed, building codes and standards. Here are some typical codes and standards for insulated doors.• ASHRAE 90.1 sets minimum energy efficiency requirements for commercial buildings, including rolling doors. It also specifies the minimum U-factor and R-value based on climate zone.

• ASTM E90 is a standard test that measures the STC rating of rolling doors.

• ANSI/DASMA 108 is a testing method that assesses how well a door can withstand wind loads.

• California Title 24 is the state's energy efficiency standards for buildings. Any rolling door installed in California has to meet specific installation and construction requirements that contribute to the overall energy efficiency of the building.

• (IECC) section C402.5.2 sets the maximum allowable air leakage rate through a door assembly and designates required testing.

RELATED: Building Codes, Listings and Project Requirements

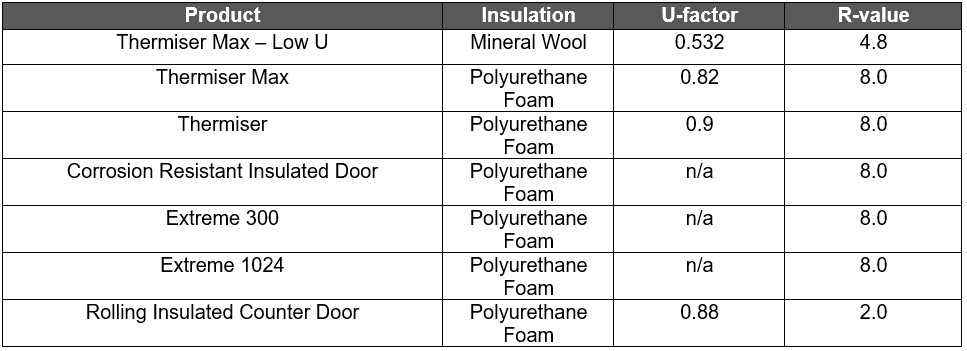

Compare Cornell Insulated Rolling Doors.

When it comes to energy efficiency, Cornell rolls straight through the competition. Our engineers go above and beyond to set the standard. And, once we set the standard, we aim to exceed it. Our relentless pursuit of perfection is reflected across our full line of insulated rolling doors.Whether you’re regulating indoor climates, reducing energy costs, or safeguarding buildings from the elements, Cornell’s cutting-edge solutions ensure you’re offering customers the most effective products available.

Insulated Rolling Doors

Thermiser®

Thermiser can be mounted on a building’s interior or exterior. Foamed-in-place polyurethane insulation helps maintain indoor temperatures, and rugged galvanized steel coated in a GalvaNex™ polyester enamel finish resists rust and corrosion.

U-factor: 0.9

Cycles: 50,000

Warranty: 2-year

Back Slat Construction: steel

Insulation: polyurethane foam

Air Infiltration Package: not available

Max Width: 30’

Powder Coat: available

STC Rating (Entire Assembly): not available

Standards: not available

Mounting: interior and exterior

Thermiser Max®

Thermiser Max set the industry standard for thermal performance. This door carries a U-factor of 0.82, the lowest in the rolling door industry, second only to our Thermiser Max - Low U. Impressive energy efficiency is thanks to a patented perimeter seal, thermally broken guide construction, and a polyurethane insulated curtain.

U-factor: 0.82

Cycles: 50,000

Warranty: 2-year

Back Slat Construction: steel

Insulation: polyurethane foam

Air Infiltration Package: available

Max Width: 30’

Powder Coat: available.

STC Rating (Entire Assembly): Up to 32 STC available.

Standards: IECC 2021, ASHRAE 90.1, California Title 24

Mounting: interior/exterior

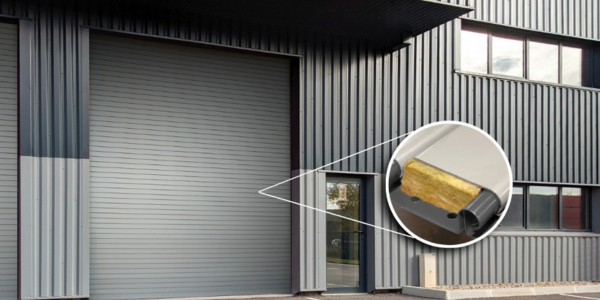

Thermiser Max® - Low U

Shattering our thermal performance record, Thermiser Max – Low U stands as our most energy-efficient model. Low-U exceeds industry standards with a U-factor rating of 0.532. The difference lies in revolutionary design details, including a CPVC backer, mineral wool insulation, thermally-broken guide, and a groundbreaking sealing system.

U-factor: 0.532

Cycles: 50,000

Warranty: 2-year

Back Slat Construction: low-smoke CPVC

Insulation: mineral wool

Air Infiltration Package: available

Max Width: 21’

Powder Coat: available (front slat only)

STC Rating (Entire Assembly): up to 27 STC available.

Standards: IECC 2021, ASHRAE 90.1, California Title 24

Mounting: interior only.

Corrosion Resistant Insulated Door

Our standard rolling and insulated doors have been reimagined for water treatment plants. The Corrosion Resistant Service and Insulated Door carries a 2-year, 50,000 cycle warranty. Doors are engineered with a ZRG powder coated shaft, zinc-coated bearings, corrosion-resistant fasteners, and the rugged NEMA 4X operator to resist red rust and oxidation.

U-factor: not available

Cycles: 50,000

Warranty: 2-year

Back Slat Construction: steel

Insulation: polyurethane

Air Infiltration Package: none

Max Width: 15’

Powder Coat: available

STC Rating (Entire Assembly): 22

Standards: ASHRAE 90.1 IECC

Mounting: interior/exterior

Insulated High Performance Doors

Extreme® 300 Series

Available in both insulated and uninsulated models, the Extreme 300 Series Door features 300,000 maintenance-free cycles. Insulated models carry an air leakage rating of less than 0.3 cfm/ft2, surpassing ASHRAE® 90.12, 2015, IECC®, and California’s Title 24 air infiltration requirements.

U-factor: not available

Cycles: 50,000

Warranty: 2-year

Back Slat Construction: steel

Insulation: polyurethane

Air Infiltration Package: standard

Max Width: 24’

Powder Coat: available

STC Rating (Entire Assembly): 32

Standards: ASHRAE 90.1, IECC

Mounting: interior/exterior

Extreme 1024

One of the most economical doors in the lineup, the Extreme 1024 Door has an impressive 5-year 1 million cycle warranty. When compared to other high-speed slatted products, the Extreme 1024 Door has the lowest lifetime cost and cost-per-cycle on the market. As another perk, the door can also be configured for operational wind loads up to 10 PSF.

U-factor: not available

Cycles: 50,000

Warranty: 2-year

Back Slat Construction: steel

Insulation: polyurethane

Air Infiltration Package: standard

Max Width: 24’

Powder Coat: available

STC Rating (Entire Assembly): not available

DOWNLOAD: Extreme Series Comparison Chart

Insulated Counter Doors

Rolling Insulated Counter Door

The only counter door of its kind, our insulated counter door features a patented PVC back slat with melamine foam insulation. The PVC backer slat eliminates metal-on-metal contact, reducing operational noise and extending the life of the finish.

U-factor: not available

Cycles: 50,000

Warranty: 2-year

Back Slat Construction: PVC

Insulation: melamine foam

Air Infiltration Package: not available

Max Width: 21’

Powder Coat: available

STC Rating (Entire Assembly): 26

Standards: not available

Mounting: interior/exterior

Insulated Door R-Values and U-Factors