Cornell Commercial Rolling Doors and Security Grilles Blog

When it comes to Overhead Rolling Doors and Grilles, we are the experts in innovative door solutions!

Subscribe

Get updates on new blog posts to your inbox!

Day in the Life of a Product Development Engineer | Cornell

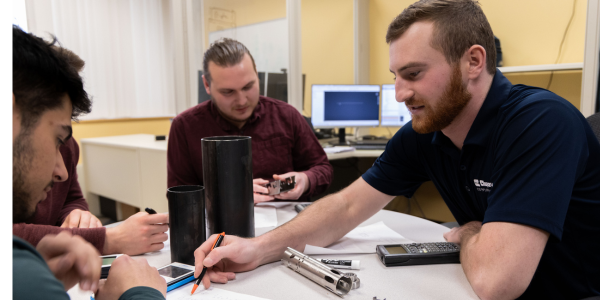

Meet Brandon Smith, New Product Development Engineer for Clopay Corporation.

It’s 3 a.m., and Brandon Smith lies in bed, watching thin shadows dance across his ceiling. His gaze shifts to a bedside table, where he can see the outlines of a notepad and pen in the dim morning light. Reaching over, he grabs the pen and quickly jots his idea down on a clean page. He sighs with relief and closes his eyes. Sinking back into the covers, he drifts back to sleep. Two hours later, his alarm trills and he rolls out of bed and gets ready for his day.

Brandon drives along the winding roads of Mountain Top to the Cornell and Cookson manufacturing facility. His footsteps echo through the corridors as he eagerly makes his way through the building. He throws open the door and greets his team, ready to present the solution that kept him up all night.

Many of Brandon’s mornings begin this way. As a new product development engineer, he’s trained to analyze problems and resolve design challenges.

“Problem-solving is part of my DNA,” says Brandon. “Every problem is an opportunity for me to create something new or make something better.”

The new product development (NPD) process starts with the design phase. In this phase, Brandon’s team conducts research, brainstorms, and analyzes product ideas. Next, they work with product designers to create 3D models of the concept. “Each part of the model is carefully molded down from a crude shape. One part soon transitions into a complete multipart assembly that includes electronics, drive systems, and sensors,” Brandon explains.

Brandon compares the NPD process to solving a Sudoku puzzle. “You’re working within a set of controlled conditions. These conditions may shift as you’re working on the puzzle, but the end game is always the same. Everything has to add up. You have to overcome all of these challenges without hindering other parts of the design.”

During the product engineering phase, Brandon and his team develop solutions to optimize the product. “As product and assembly testing begins, we focus on ways to improve upon the quality and design. Through multiple iterations, we enhance the design’s aesthetics, function, manufacturability, and cost- just to name a few,” said Brandon.

A prototype is created and launched into the market in the final development phase. From there, Brandon and his team gather feedback and begin to refine the product’s performance.

“The whole process is a mixture of trial-and-error and logic,” said Brandon. “Working at Clopay, I get to collaborate with my fellow engineers to transform concepts into reality. I get to be a part of this high-energy and fun-filled journey that brings innovative commercial garage door products to our customers.”